Durability testing is a testing type applied to components to determine their expected life. In another saying, it is a performance testing technique which is used to determine the characteristics of a system or product under various load conditions over time. Real forces and motions that are collected from a system level can be re-generated and applied to the component to replicate its in-service conditions. Durability tests are required to validate product design in terms of design life.

- Up to 50 Hz test frequency range in durability tests

- Up to ±50 kN force range capacity

- Up to ±75 mm displacement range capacity

- Translational or rotational directions

- Uni-axial durbility test bench

- Tri-axial translational test bench

- Multi-axis bushing durability test bench

- Sinusoidal durability tests

- Advanced peak-valley compansation algorithm

- Advanced amplitude-phase compansation algorithm

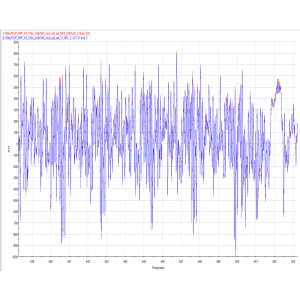

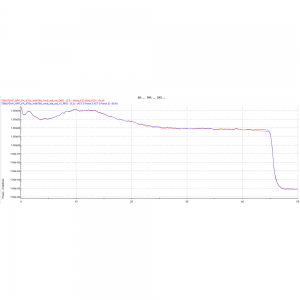

- Trend monitoring from force and/or displacement responses

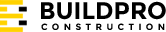

- RLD durability tests

- Single axis

- Multi-axis

- Road load data type based force response

- Road load data type based displacement response

- Calculating drive file using MTS-cRPC software by iterations

- Experience in preparing accelerated response from raw RLD’s.

- Experience in life prediction from response signal using FEA tools

- Trend monitoring from force and/or displacement responses