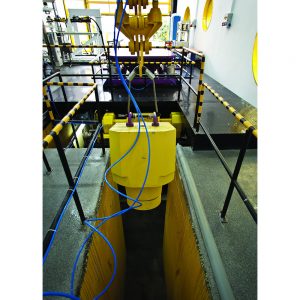

The Medium Weight Shock Machine (MWSM) was first developed in 1942, based on the US Navy’s satisfaction with the Lightweight Shock Machine (LWSM) and the need to shock qualify even heavier items. The MWSM can accommodate components ranging in weight up to 7400 lbs and it utilizes hammer impact to transmit shock loading upon the component to be tested. The MWSM at the Tekno-ETA shock testing laboratory is designed and built according to specifications defined in MIL-S-901D standard.

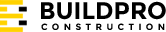

The component is fixed above a massive anvil table which is 4400 lb (~2000 kg) , is struck by a 3000 lb (~1360 kg) hammer. The MWSM is permanently installed at our facility, such that the hammer swings through a hole in the floor and strikes the anvil table.

In MIL-S-901D standard, the test conditions have been defined without any SRS (Shock Response Spectrum) envelope specifications. The testing parameters that determines the shock load to be applied to the system under test like height of the anvil plate, supporting channel shapes, bolt holes patterns, the mass over the anvil plate and hammer drop height are predefined.

For all items subject to medium weight shock testing, a minimum of six blows (of three groups of two blows each) shall be applied. For each group, the height of the hammer, number of blows, and anvil table travel changes according to tables defined in the standard documentation. One blow of each group shall be conducted with the tested item mounted in its normal attitude ( to simulate shipboard shock loadings in the vertical direction). The other blow of each group shall be conducted with the tested item mounted in the inclined position ( to simulate shipboard shock loadings in the athwartship direction).

In addition to MIL-S-901D standard needs, provisional PV-SRS curves can be considered either to predict the shock input levels or to compare a different type shock input with the shock generated during testing by instrumenting the system with shock grade accelerometers and collecting data during each blows.

In Tekno-ETA, beside MIL-S-901D testing, SRS Based shock tests are able to be carried out using Medium Weight Shock Machine (i.e. BV0430 and STANAG 4141). We are also able to carry out shock tests using equivalent SRS values of classical shock profiles such as terminal peak sawtooth and half-sine for the systems to be tested that exceeds the mass limits of electrodynamic shakers.